Refurbish Process Of Lead-Acid Batteries

The process of refurbishing lead-acid batteries involves various methods to restore them to a functional state, extending lifespan and optimizing performance.

Used Batteries

Used lead-acid batteries" are batteries that have been previously used in different applications, and have now reached the end of their initial service life. These batteries contain lead-acid, which is commonly found in automotive batteries, uninterruptible power supplies (UPS), and other industrial applications.

The process of refurbishing lead-acid batteries involves various methods to restore them to a functional state, extending lifespan and optimizing performance.

The battery is thoroughly cleaned to remove any dirt, debris, or corrosion. A visual inspection is performed to identify any physical damage or wear.

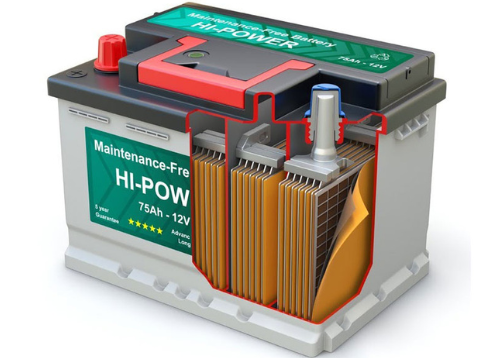

The battery is dismantled to access its individual components such as lead plates, electrolyte, and casing.

Various tests are conducted to assess the condition of the battery, including voltage measurement, capacity measurement, internal resistance measurement, and electrolyte specific gravity measurement.

Techniques such as equalization charging, desulfation, or chemical treatments may be applied to restore battery capacity and performance, depending on its condition.

Damaged or worn-out components, such as corroded terminals or deteriorated separators, may be replaced with new ones to ensure optimal functioning.

The refurbished battery undergoes rigorous testing to ensure its performance and reliability. This includes capacity, load, and cycling tests to simulate real-world conditions.

A final inspection is performed to verify that the refurbished battery meets quality standards. Then, it is appropriately packaged for storage or shipment.